How to Read a Relay Diagram Gm

Relay Guide Overview What is a relay? A relay is substantially a switch that is operated electrically rather than mechanically. Although in that location are diverse relay designs, the ones about commonly found in low voltage machine and marine applications are electro-mechanical relays that piece of work by activating an electromagnet to pull a set up of contacts to make or break a circuit. These are used extensively throughout vehicle electric systems. Why might I want to apply a relay? There are several reasons why you might desire or need to utilise a relay:

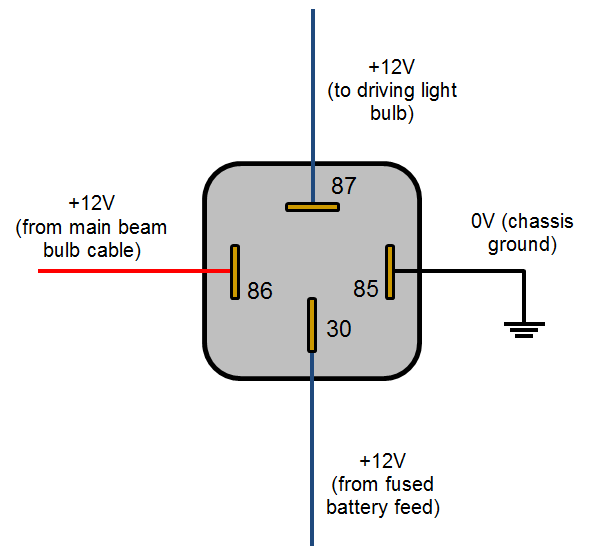

This is the most common reason and useful where an in-line switch or the existing circuit does non take the capacity to handle the current required. For instance, if you lot wanted to fit some high power work lights that come on with the headlights but there is a run a risk that they would exceed the capacity of the existing loom.

High current chapters wiring and switches cost more than than lower electric current capacity versions, so by using relays the requirement for the more than expensive components is minimised.

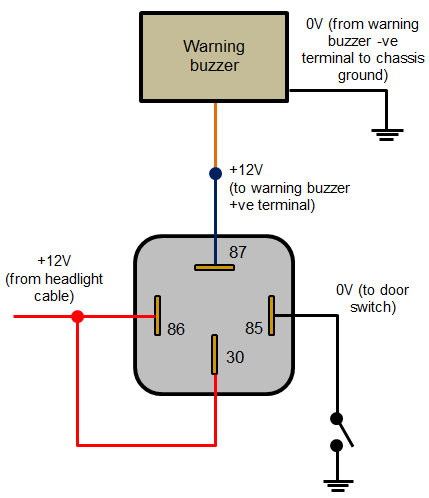

Y'all can apply a single input from one office of an electrical system (eastward.one thousand. cardinal locking output, transmission switch etc.) to actuate one or more relays that then consummate one or more other circuits and and so carry out multiple functions from i input bespeak.

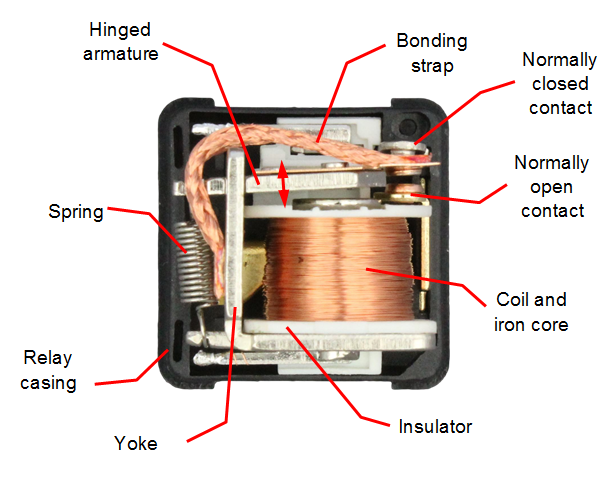

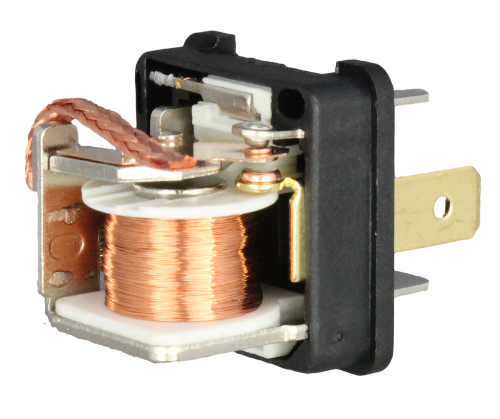

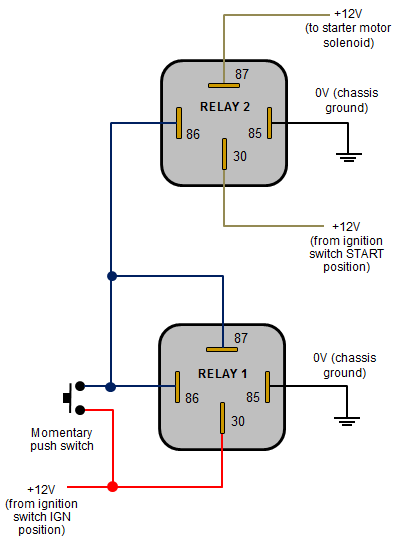

Electromagnetic relays tin can be put to some quite clever (and complex) applications when linked upwardly to perform logical operations based on certain inputs (for case, latching a +12V output on and off from a momentary input, flashing alternative left and correct lights etc.). Although these logical functions accept now been superseded by electronic modules for OEM designs, it can still be useful, fun and often more cost effective to utilize relays to perform them for some after-market projects (particularly where yous have a bespoke application). Note: In this article we are going to focus on ISO mini or 'standard' relays which have a 1" cube body and are the most commonly used in vehicle electric systems. Structure and operatio northward Inside a relay This is what the inside of an ISO mini relay looks like:

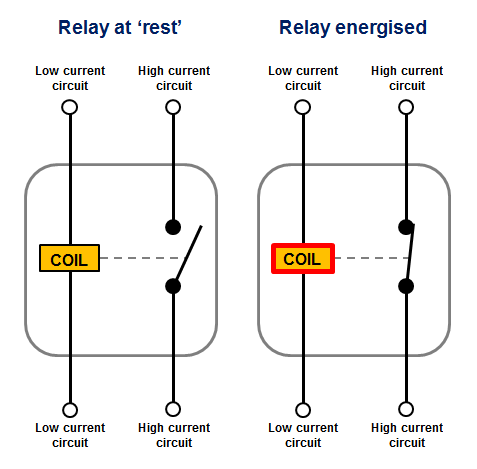

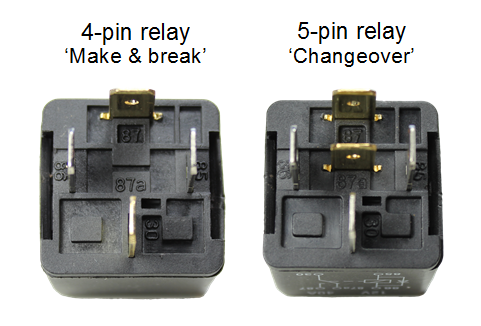

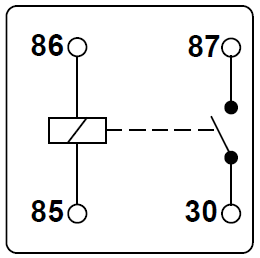

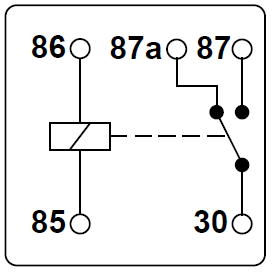

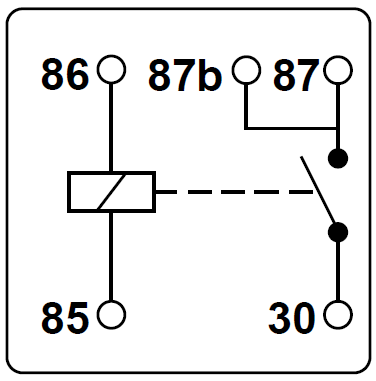

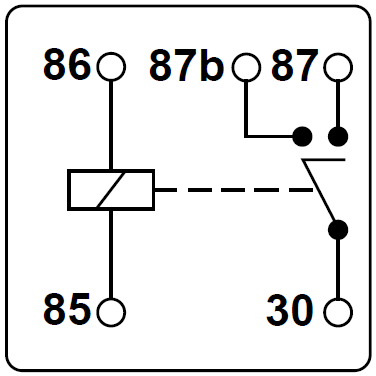

A copper coil effectually an atomic number 26 core (the electromagnet) is held in a frame or 'yoke' from which an armature is hinged. I end of the armature is connected to a tension jump which pulls the other end of the armature up. This is the relay in its de-energised state or 'at rest' with no voltage applied. The braided bonding strap provides a skillful electrical connection between the armature and yolk, rather than relying on contact between the armature pivot point lonely. The coil and contact (or contacts) are then connected to various terminals on the outside of the relay trunk. How they work When the coil is supplied with voltage a magnetic field is generated around it which pulls the hinged armature downwardly onto the contact. This completes the 'loftier' current excursion between the terminals and the relay is said to be energised. When voltage is removed from the coil terminal the spring pulls the armature dorsum into it's 'at rest' position and breaks the circuit between the terminals. And so by applying or removing power to the roll (the low current circuit) nosotros switch the high electric current circuit on or off. Note: It is important to empathize that the roll circuit and the electric current-conveying (or switched) circuit are electrically isolated from one some other within the relay. The coil circuit simply switches the high electric current circuit on. The following simplified circuit diagram is oft used to easily understand how a relay operates: Relay terminology The ISO mini relay we accept looked at above has 4 pins (or terminals) on the body and is referred to equally a brand & break relay because in that location is one high current circuit and a contact that is either open or closed depending upon whether the relay is at residual or energised. If the contact is cleaved with the relay at rest then the relay is referred to asNormally Open(NO) and if the contact is airtight with the relay at residuum then the relay is referred to every bit Normally Closed (NC). Normally Open relays are the more common type. ISO mini relays with two circuits, 1 of which is closed when the relay is at remainder and the other which is airtight when the relay is energised, take 5 pins on the body and are referred to equally changeover relays. These take two contacts connected to a mutual terminal. Brand & break relays are also known as Unmarried Pole Single Throw (SPST) and changeover relays as Single Pole Double Throw (SPDT). This is based on standard switch terminology. There are other contact configurations discussed below but brand & intermission and changeover relays are the most commonly used. Final numbering convention The terminal numberings found on a relay torso are taken fromDIN 72552 which is a German automotive industry standard that has been widely adopted and allocates a numeric code to diverse types of electrical terminals constitute in vehicles. The terminals on the outside of a 4 or five pin mini relay are marked with numbers every bit shown below:

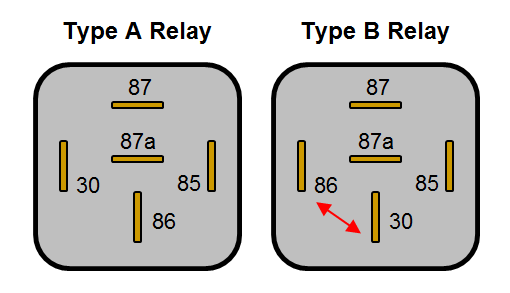

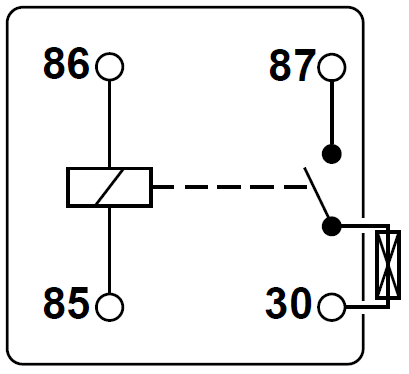

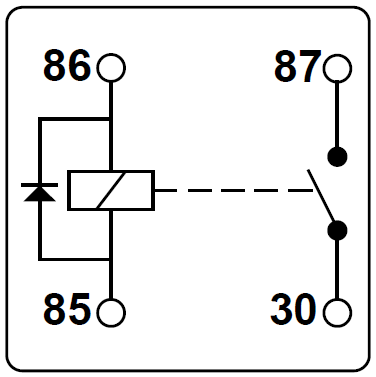

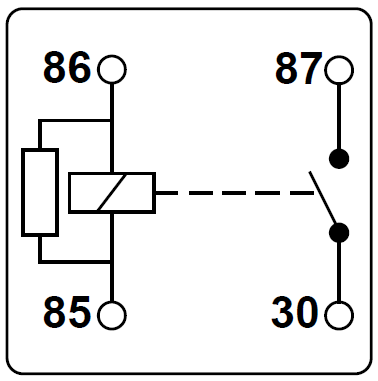

Co-ordinate to DIN 72552 the roll should be fed with +12V to last 86 and grounded via terminal 85, however in practise it makes no deviation which manner effectually they are wired, unless yous are using a relay with an integrated diode (see more info on diodes below). Tip: you tin use a changeover relay in identify of a make & break relay by just leaving either the NO or NC final disconnected (depending on whether you want the circuit to be made or broken when you energise the relay). Concluding layouts The automotive ISO mini relays nosotros take been looking at above are typically available in two types of pivot layout designated Type A and Blazon B layouts. These layouts are shown on the two v-pivot relays beneath (pivot 87a not present on 4 pin relays): You will notice that on the Type B layout pins 86 and 30 are swapped over compared with the Type A layout. The Type B layout is arguably easier to piece of work with as the connected terminals are in-line, making the wiring easier to visualise. If you lot need to replace a relay make sure you use 1 with the same terminal layout as it is piece of cake to overlook if you're non aware of the difference. Terminal sizes The terminal widths used on 4 and 5 pin relays are almost always 6.3mm wide, however some more than specialist relays can have terminal widths of 2.8mm, four.8mm and nine.5mm. The 9.5mm wide terminals tend to exist used for college ability applications (such every bit for starter motor solenoid activation) and the smaller terminals tend to be used for electronics signalling where merely very low currents are required. All widths will be uniform with the standard female blade crimp terminals of the corresponding sizes. Relay body markings Relays can wait very similar from the outside then they normally accept the excursion schematic, voltage rating, electric current rating and terminal numbers marked on the trunk to identify them.

This shows the basic internal circuits (including any diodes, resistors etc.) and concluding layout to assist wiring.

The operating voltage of the coil and high current circuits. Typically 12V for rider vehicles and pocket-sized craft but also bachelor in 6V for older vehicles and 24V for commercial applications (both auto and marine).

This is the current carrying capacity of the high current circuit(s) and is normally between 25A and 40A, notwithstanding it is sometimes shown as a dual rating on changeover relays due east.g. 30/40A. In the case of dual ratings the normally closed circuit is the lower of the ii, so 30A/40A, NC/NO for the example given. The current describe of the scroll is non normally shown but is typically 150-200 mA with a respective coil resistance of effectually 80-60W. Tip: Knowing the coil resistance is useful when testing the relay for a mistake with a multi-meter. A very high resistance o r open circuit reading can indicate a damaged coil.

The numbers 85, 86, 30, 87 & 87a (or other numbers for different relay configurations) are commonly moulded into the plastic next to each pin and also shown on the circuit schematic. Relay configurations and types In improver to the basic brand & break and changeover configurations above, ISO relays are available in a number of other common configurations which are described in the table below:

* All schematics shown with the relay at residuum (de-energised) Micro relays ISO micro relays are, equally the proper noun suggests, smaller than ISO mini relays and designed for employ in applications where space is at a premium. They are rectangular in section and narrower than a mini relay with a slightly different pin layout, and are typically bachelor in 'make and break' and 'changeover' configurations, with and without suppression diodes. In addition, the terminal numbering is different, using one, two, 3, iv & 5 instead of 30, 85, 86, 87 & 87a.

More complex relay types There are other relay designs that are used for some more complex applications in vehicle systems. They are nonetheless based upon the principle of switching higher current circuits using smaller current circuits but often combine this with electronics to perform special functions: Some examples are:

These more complex relays can have up to 9 pins of various sizes. This increment in the number of terminals over the standard 4 or 5 in more simple relays is often necessary considering boosted connections can be required for the in-congenital electronics (eastward.g. inputs from sensors or the ECU and outputs to indicator lights or the ECU). Example relay wiring schemes The post-obit diagrams prove some mutual relay wiring schemes that use iv pin ISO mini relays.

Disclaimer The information contained in these manufactures is provided in good faith and we do our all-time to ensure that it is accurate and up to date, yet, we cannot be held responsible for any damage or loss arising from the use or mis-use of this information or from any errors or omissions. The installer is ultimately responsible for the safety of the organisation so if you are in whatsoever uncertainty, please consult a qualified electrician. | Watch our YouTube "how to" guides hither Discover out about our Trade Accounts here | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Source: https://www.12voltplanet.co.uk/relay-guide.html

0 Response to "How to Read a Relay Diagram Gm"

Publicar un comentario